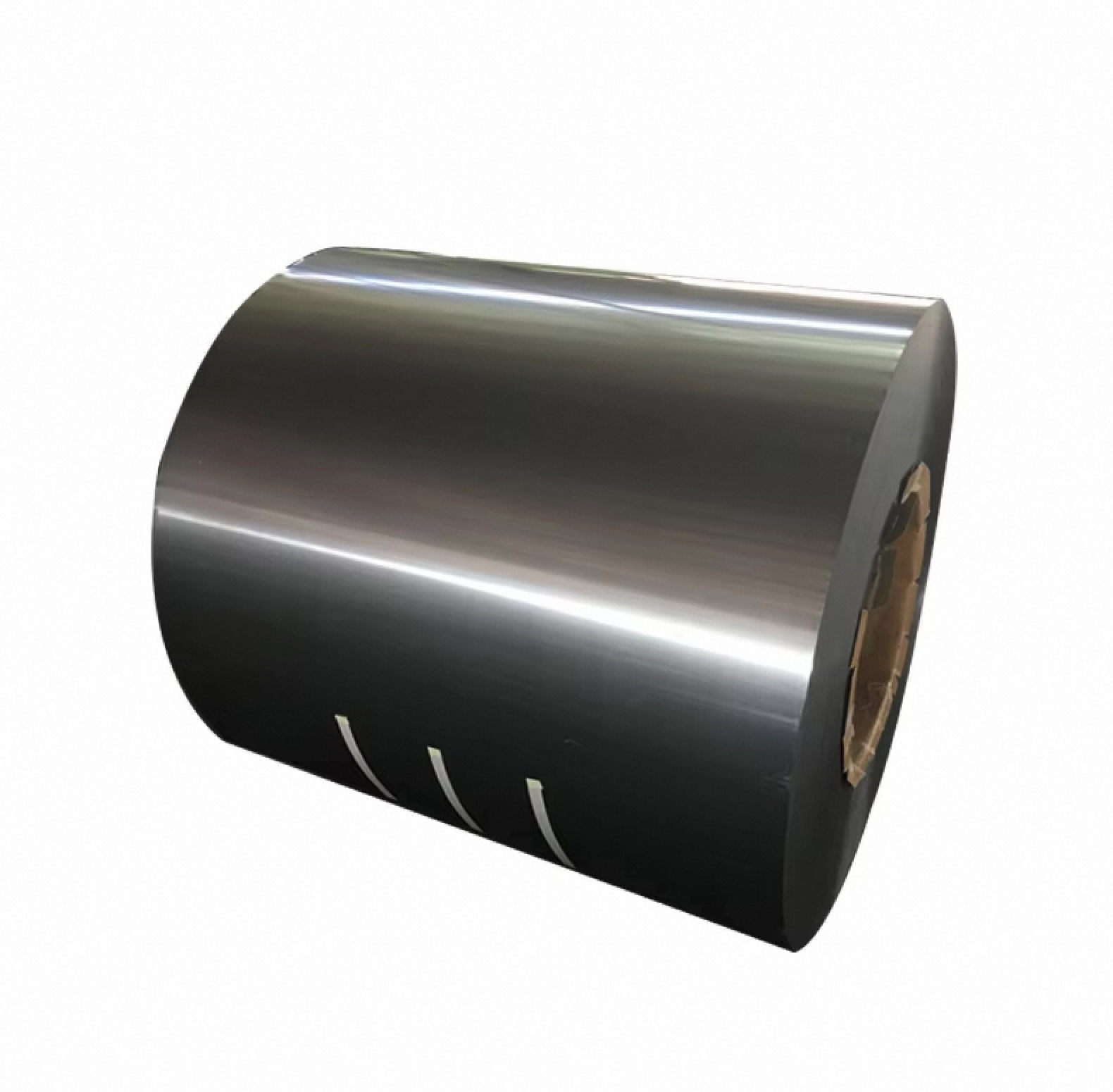

50w600 50w800 50w1300 Non Oriented and Grain Oriented Cold Rolled Magnetic Induction Electrical Silicon Steel Coil Transformer

- Overview

- Related Products

Description of Electrical Silicon Steel

Electrical steel is mainly divided into GO electrical steel and NGO electrical steel two categories. Easy magnetization direction of GO electrical steel distribution along the rolling direction, the direction of rolling with high induction, excellent characteristics such as low iron loss refinement processing technology, lower iron loss of performance, and are widely used in the transformer industry.

The difference between oriented silicon steel and non-oriented silicon steel

Non-oriented silicon steel: ferrosilicon alloy with very low carbon content. In the deformed and annealed steel sheet, its grains are distributed randomly. The silicon content of the alloy is 1.5% to 3.0%, or the sum of the silicon and aluminum content is 1.8% to 4.0%. The Products are usually cold-rolled plates or strips, which are mainly used to manufacture motors and generators.

Oriented silicon steel: It has strong directionality, the lowest iron loss value in the rolling direction, the highest magnetic permeability, and a higher magnetic induction value under a certain magnetization field. The silicon content of oriented silicon steel is about 3%. It also requires a low content of oxide inclusions in the steel and must contain certain inhibitors (MnS, A1N).

Material Grade |

0.2mm |

0.23mm |

0.27mm |

0.30mm |

China Grade |

B20R070, B20R075, B20R080 |

23R075,23R080, 23R085,23R090, 23P090,23P095, 23P100 |

B27R085,B27R090, B27P090,B27P095, |

B30P095,B30P100, B30P105,B30P110, |

Japan Grade |

|

23R075,23R080, 23R085,23R090, |

27R085,27R090, 27P090,27P095, 27P100,27P110, 27G120,27G130 |

30P095,30P100, 30P105,30P110, 30G120,30G130 |

Korea Grade |

|

23PHD080,23PHD085, 23PHD090,23PH090, 23PH095,23PH100 |

27PHD085,27PHD090, 27PH090, 27PH095,27PH100,27PG110, |

30PH095,30PH100, 30PH105,30PH110, |

Grade |

Yeild Strength(N/mm2) |

Ultra-TensionStrength(N/mm2) |

Ductility(%) |

Hardness(HV1) |

M35W230 |

430 |

560 |

20.0 |

225 |

M35W250 |

415 |

550 |

20.5 |

220 |

M35W270 |

400 |

515 |

20.5 |

215 |

M35W300 |

360 |

480 |

21.5 |

195 |

M35W360 |

350 |

480 |

23.5 |

190 |

M35W440 |

275 |

420 |

27.5 |

165 |

M35W550 |

265 |

415 |

33.5 |

160 |

M50W250 |

430 |

560 |

19.0 |

230 |

M50W270 |

410 |

550 |

21.5 |

225 |

M50W290 |

395 |

545 |

22.5 |

220 |

M50W310 |

385 |

510 |

24.5 |

210 |

M50W350 |

350 |

475 |

26.5 |

190 |

M50W400 |

320 |

460 |

36.0 |

170 |

M50W470 |

295 |

425 |

35.0 |

160 |

M50W600 |

280 |

410 |

37.0 |

140 |

M50W800 |

285 |

405 |

38.5 |

135 |

M50W1300(D) |

250 |

360 |

40.0 |

115 |